Key Product Attributes:

| FEATURE | DETAIL |

| MATERIAL AND GRADE | Stainless Steel 304 (SS304), Stainless Steel 304L (SS304L), Stainless Steel 316 (SS316), Stainless Steel 316L (SS316L), Stainless Steel 430 (SS430) (with options) excellent corrosion resistance & durability |

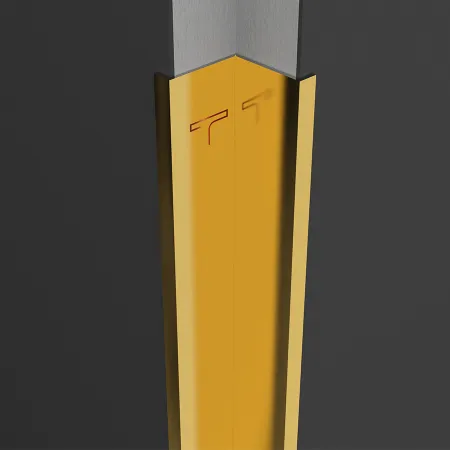

| COATING | PVD Titanium Coated (Physical Vapor Deposition) enhanced wear resistance, durability and aesthetics. |

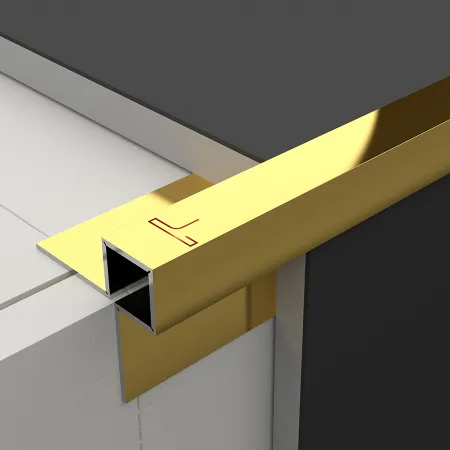

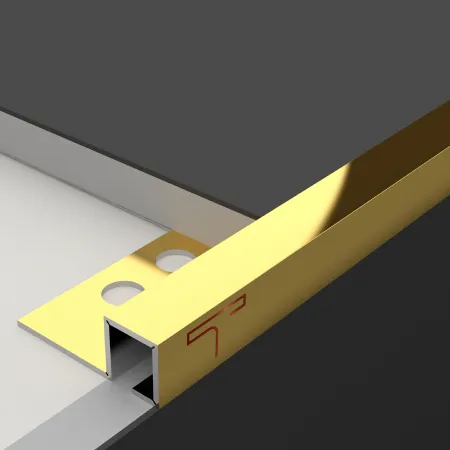

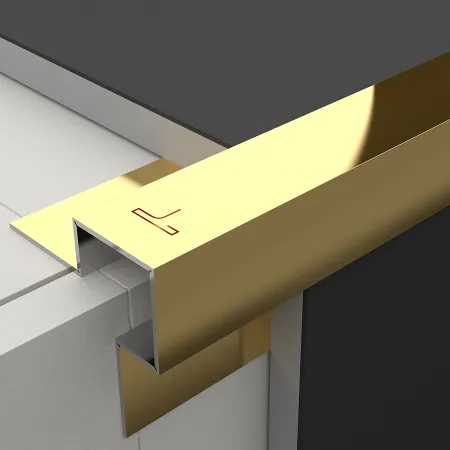

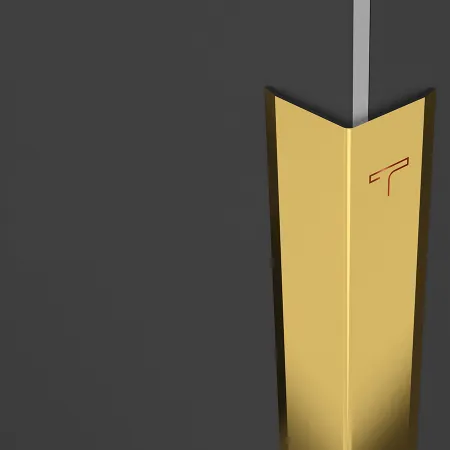

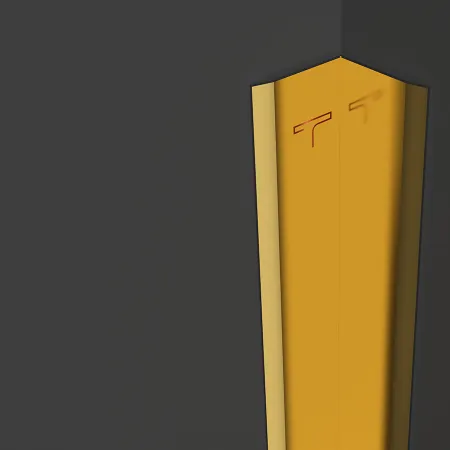

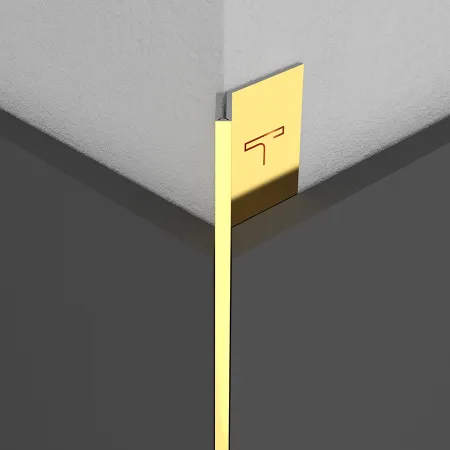

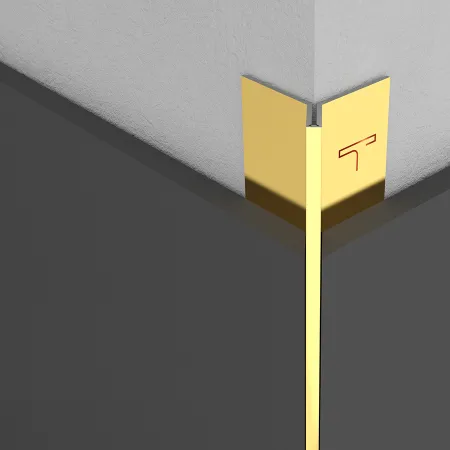

| PROFILE TYPE | SS Corner Guards (structural strength, clean design) |

| CODES |

C-K1 - Equal Box Corner Protection Profile - Type - 1 C-A3 - 'A' Corner Shape Corner Protection Profile C-K2 - Equal Box Corner Protection Profile - Type - 2 C-L1 - L Type Corner Profile C-L2 - Clamp L Profile - Type - 1 C-L3 - Clamp L Profile - Type - 2 C-L4 - Extended L Profile C-Y1 - Y Profile - Type - 1 C-Y2 - Y Profile - Type - 2 |

| COLORS WITH DIFFERENT SURFACE FINISHES | Colors Available In Mirror Surface Finish Silver, Gold, Rose Gold, Black, Nickel Silver, Champagne Gold, Tea and Copper |

| Colors Available In Hairline Surface Finish Silver, Gold, Rose Gold, Black, Nickel Silver, Champagne Gold, Tea, Copper, Antique Brass, Antique Copper, Antique Bright Copper, Antique Bronze and Antique Green Copper | |

| Colors Available In Satin Surface Finish Silver, Gold, Rose Gold, Black, Nickel Silver, Champagne Gold, Tea and Copper | |

| Colors Available In Straight lines Surface Finish Silver, Gold, Rose Gold, Black, Nickel Silver, Champagne Gold, Tea and Copper | |

| Colors Available In Mesh Surface Finish Silver, Gold, Rose Gold, Black, Nickel Silver, Champagne Gold, Tea and Copper | |

| Colors Available In Sparkling Starlight Surface Finish Silver, Nickel Silver, Black, Copper and Tea | |

| Colors Available In Pattern Etched Surface Finish Silver Copper, Copper | |

| Colors Available In Pattern Elegant Etched Surface Finish Bronze Rose, Grey Nickel | |

| Colors Available In Pattern Chequered Surface Finish Black | |

| Colors Available In Cross Hairline Surface Finish Antique Brass, Antique Bronze, Antique Copper, Antique Bright Bronze and Antique Green Copper | |

| LENGTH | 8 Ft, 10 Ft The Length can be customized as per your requirement. |

| SS CORNER GUARDS SIZES (MM) (W X H) | 12 (mm), 20x12 (mm), 5x15x15 (mm)

The Size can be customized based on your requirement. |

| THICKNESS | 0.8 mm, 1.2 mm For 1.2 mm thickness, Some sizes are based on our machine capabilities. |

| DOUBLE PROTECTIVE FILM | All our SS Corner Guards are protected with Novacel/ Polyfilm/Nitto laser protective films, depending on the requirement. They are either protected with a Double layered protective film of 70 microns (laser) + 30 microns (Non - laser) or a single layered laser protective film of 100 microns. |

Product Availability Chart : Color, Surface Finish Type, Thickness & Application Use

| Category | Colours | Surface Finish | Coating | Micron Coating (micro) | Thickness in mm | Application Use | |

|---|---|---|---|---|---|---|---|

| Indoor | Outdoor | ||||||

| Colors | Ti-Tea | Mirror | PVD | 0.2µ~0.3µ | 0.8 |  |  |

| Hairline | PVD | 0.2µ~0.3µ | 1.2 | ||||

| Mesh | PVD | 0.2µ~0.3µ | 0.8 & 1.2 | ||||

| Satin | PVD | 0.2µ~0.3µ | 0.8 & 1.2 | ||||

| Straight lines | PVD | 0.2µ~0.3µ | 1.2 | ||||

| Colors | Ti-Rose Gold | Mirror | PVD | 0.2µ~0.3µ | 0.8, 1 & 1.2 |  |  |

| Hairline | PVD | 0.2µ~0.3µ | 0.8 & 1 | ||||

| Mesh | PVD | 0.2µ~0.3µ | 1.2 | ||||

| Satin | PVD | 0.2µ~0.3µ | 0.8 & 1.2 | ||||

| Straight lines | PVD | 0.2µ~0.3µ | 0.8 & 1.2 | ||||

| Colors | Ti-Champagne Gold | Mirror | PVD | 0.2µ~0.3µ | 0.8 & 1 |  |  |

| Hairline | PVD | 0.2µ~0.3µ | 0.8 & 1 | ||||

| Mesh | PVD | 0.2µ~0.3µ | 1.2 | ||||

| Satin | PVD | 0.2µ~0.3µ | 0.8 & 1.2 | ||||

| Straight lines | PVD | 0.2µ~0.3µ | 1.2 | ||||

| Colors | Ti-Gold | Mirror | PVD | 0.2µ~0.3µ | 0.8, 1 & 1.2 |  |  |

| Hairline | PVD | 0.2µ~0.3µ | 0.8 & 1 | ||||

| Mesh | PVD | 0.2µ~0.3µ | 0.8 & 1.2 | ||||

| Satin | PVD | 0.2µ~0.3µ | 1.2 | ||||

| Straight lines | PVD | 0.2µ~0.3µ | 0.8 & 1.2 | ||||

| Colors | Ti-Nickel Silver | Mirror | PVD | 0.2µ~0.3µ | 0.8 |  |  |

| Hairline | PVD | 0.2µ~0.3µ | 0.8 & 1.2 | ||||

| Mesh | PVD | 0.2µ~0.3µ | 1.2 | ||||

| Satin | PVD | 0.2µ~0.3µ | 0.8 & 1.2 | ||||

| Straight lines | PVD | 0.2µ~0.3µ | 1.2 | ||||

| Colors | Ti-Copper | Mirror | PVD | 0.2µ~0.3µ | 0.8 |  |  |

| Hairline | PVD | 0.2µ~0.3µ | 0.8 | ||||

| Mesh | PVD | 0.2µ~0.3µ | 1.2 | ||||

| Satin | PVD | 0.2µ~0.3µ | 0.8 & 1.2 | ||||

| Straight lines | PVD | 0.2µ~0.3µ | 0.8 & 1.2 | ||||

| Colors | Black | Mirror | Chemical | 0.2µ~0.3µ | 0.8 & 1 |  |  |

| Hairline | Chemical | 0.2µ~0.3µ | 0.8 | ||||

| Mesh | Chemical | 0.2µ~0.3µ | 0.8 & 1.2 | ||||

| Satin | Chemical | 0.2µ~0.3µ | 0.8 & 1.2 | ||||

| Straight lines | Chemical | 0.2µ~0.3µ | 0.8 & 1.2 | ||||

| Colors | Silver | Mirror | N/A | N/A | 0.8, 1 & 1.2 |  |  |

| Hairline | N/A | N/A | 0.8 | ||||

| Mesh | N/A | N/A | 1.2 | ||||

| Satin | N/A | N/A | 1.2 | ||||

| Straight lines | N/A | N/A | 1.2 | ||||

| Antique | Antique Brass With AFP | Hairline | Chemical | 5µ~10µ | 0.8 & 1 |  |  |

| Antique Bronze With AFP | Hairline | Chemical | 0.2µ~0.3µ | 0.8 & 1 | |||

| Antique Green Copper With AFP | Hairline | Chemical | 5µ~10µ | 0.8 & 1 | |||

| Antique Bright Copper With AFP | Hairline | Chemical | 5µ~10µ | 0.8 | |||

| Antique Copper With AFP | Hairline | Nano | 0.2µ~0.3µ | 0.8 | |||

| Sparkling Starlight | Ti-Tea | Sparkling Starlight | PVD | 0.2µ~0.3µ | 0.8 |  |  |

| Ti-Copper | Sparkling Starlight | PVD | 0.2µ~0.3µ | 0.8 |  |  | |

| Ti-Nickel Silver | Sparkling Starlight | PVD | 0.2µ~0.3µ | 0.8 |  |  | |

| Silver | Sparkling Starlight | N/A | N/A | 0.8 |  |  | |

| Black | Sparkling Starlight | Chemical | 0.2µ~0.3µ | 0.8 |  |  | |

| Pattern | Black | Chequered | Chemical | 10µ ~ 20µ | 0.8 |  |  |

| Ti-Grey Nickel | Elegant Etched | PVD | 0.2µ~0.3µ | 0.8 |  |  | |

| Ti-Bronze Rose | Elegant Etched | PVD | 0.2µ~0.3µ | 0.8 |  |  | |

| Silver Copper With AFP | Etched | Chemical | 5µ~10µ | 0.8 |  |  | |

| Ti-Copper | Etched | PVD | 0.2µ~0.3µ | 0.8 |  |  | |

| Cross Hairline | Antique Copper With AFP | Cross Hairline | Nano | 0.2µ~0.3µ | 0.8 |  |  |

| Antique Brass With AFP | Cross Hairline | Chemical | 5µ~10µ | 1.2 | |||

| Antique Bronze With AFP | Cross Hairline | Nano | 0.2µ~0.3µ | 0.8 | |||

| Antique Bright Bronze With AFP | Cross Hairline | Chemical | 5µ~10µ | 0.8 | |||

| Aatique Green Copper With AFP | Cross Hairline | Chemical | 5µ~10µ | 0.8 | |||

Versatile Usage & Applications

Corner Guards & L profiles are widely used in both residential and commercial interiors due to their sleek finish and functional support.- Wall corners in homes, offices and hotels.

- Bathroom and kitchen tile edges.

- Staircase walls and corridor ends.

- Decorative edges on counters, columns or partitions.

Why Choose Metalpatti for Corner Guards & L Profiles ?

- Premium Quality : We use SS 304 stainless steel for superior rust resistance and strength.

- Vast Color Range : 60+ PVD finish options to suit any interior theme.

- Precision Engineering : Clean bends, uniform finishes and exact sizing for a flawless finish.

- Direct from Manufacturer : Get better pricing and consistent quality from India’s trusted metal profile supplier.

- Custom Solutions : Profiles available in different lengths,thicknesses and finishes as per your project needs.

Installation & Maintenance

- Apply to the outer edges of pillars or columns to enhance durability and create a clean design line.

- Press the L profile firmly onto the corner and ensure it is level.

- Use clamps or masking tape if necessary until the adhesive sets.

- Wipe clean with a soft cloth using mild soap and water.

- Avoid using strong chemicals or abrasive scrubbers.

- Remove the protective film after installation for a flawless finish.

Do’s and Don’ts List for Corner Protection Profiles & L Profile

| Do's | Details |

| Use Only on Interior Surfaces (unless exterior grade) | Best suited for indoor use unless specified for outdoor/weather resistant applications. |

| Handle with Clean Gloves | Avoids fingerprints, smudges and scratches. |

| Inspect Before Installation | Check for defects before cutting or fitting. |

| Use Proper Cutting Tools (Non-Abrasive) | Prevents chipping or heat discoloration during cutting. |

| Clean with Soft Cloth and Mild Cleaner | Use neutral pH cleaners and microfiber cloths. |

| Protect with Film/Tape During Installation | Keeps surface protected until final placement. |

| Use Silicon, Araldite, Kerala sticks or Neutral Adhesive (Non Acidic) | Prevents chemical reaction or staining. |

| Maintain Regularly | Regular wiping retains shine and avoids buildup. |

| Don’ts | Details |

| Don’t Use Abrasive Cleaners or Tools | Avoids scratching or damaging the surface. |

| Don’t Peel Protective Film Too Early | Prevents scratches or dust during installation. |

| Don’t Cut Without Surface Protection | Protect decorative layer with tape while cutting. |

| Don’t Use in Chlorine or Salt-Rich Environments (unless marine-grade) | Avoid corrosion in pool or coastal areas. |

| Don’t Store in Direct Sunlight or Humid Areas | Prevents UV damage and moisture-related issues. |

| Don’t Ignore Scratches or Dents | Replace damaged pieces immediately to avoid visual defects. |

Frequently Asked Questions – Corner protection profile

| Q1. What is a Corner protection profile? |

| A Corner protection profile is a trim designed to protect and reinforce the corners of walls, furniture or other surfaces, preventing damage and wear. |

| Q2. What are the common applications of a Corner protection profile? |

| Corner protection profiles are used to protect wall corners, furniture edges and areas from impact and wear, while also providing a clean and finished look. |

| Q3. Can Corner protection profiles be customized? |

| Yes, Corner protection profiles can be customized in terms of size, material, color and finish to meet specific design requirements. |

| Q4. How is a Corner protection profile installed? |

| A Corner protection profile is installed by securing it to the corner with adhesive, screws or clips, depending on the material and application. |

| Q5. Are Corner protection profiles available in different colors and finishes? |

| Yes, Corner protection profiles come in 60+ colors and finishes, including Mirror, Hairline, Satin, Straight Lines, Mesh, Antique, Sparkling, Pattern and Cross-hairline. |

| Q6. Which SS grades are used for making protection profiles ? |

| SS 304, SS 316 and SS 430 are used depending on the application and environment. |

Raw Material

We stock up to 10,000 Stainless Steel PVD Sheets for our T Profile, ensuring prompt delivery. Our finished stock certifies the quality before reaching clients. Effective inventory management enables us to provide professional service and high-quality materials.

Latest Machinery

Our Stainless Steel Decorative T profile are created using advanced cutting technology, precise V grooving machines and a 7-axis press brake by Amada. These modern manufacturing methods guarantee high accuracy and quality in our products.

Handling and Packaging

With a supervised handling system, we prioritize accurate dimensions, strict safety procedures, and flawless product delivery. Quality and safety are our top priorities in serving our customers.